Autonomous Sumo Robot

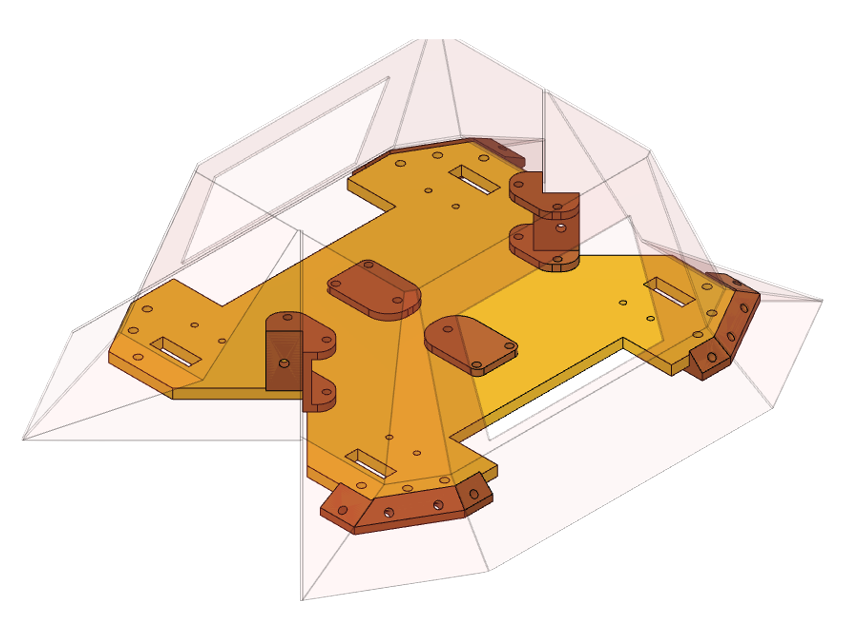

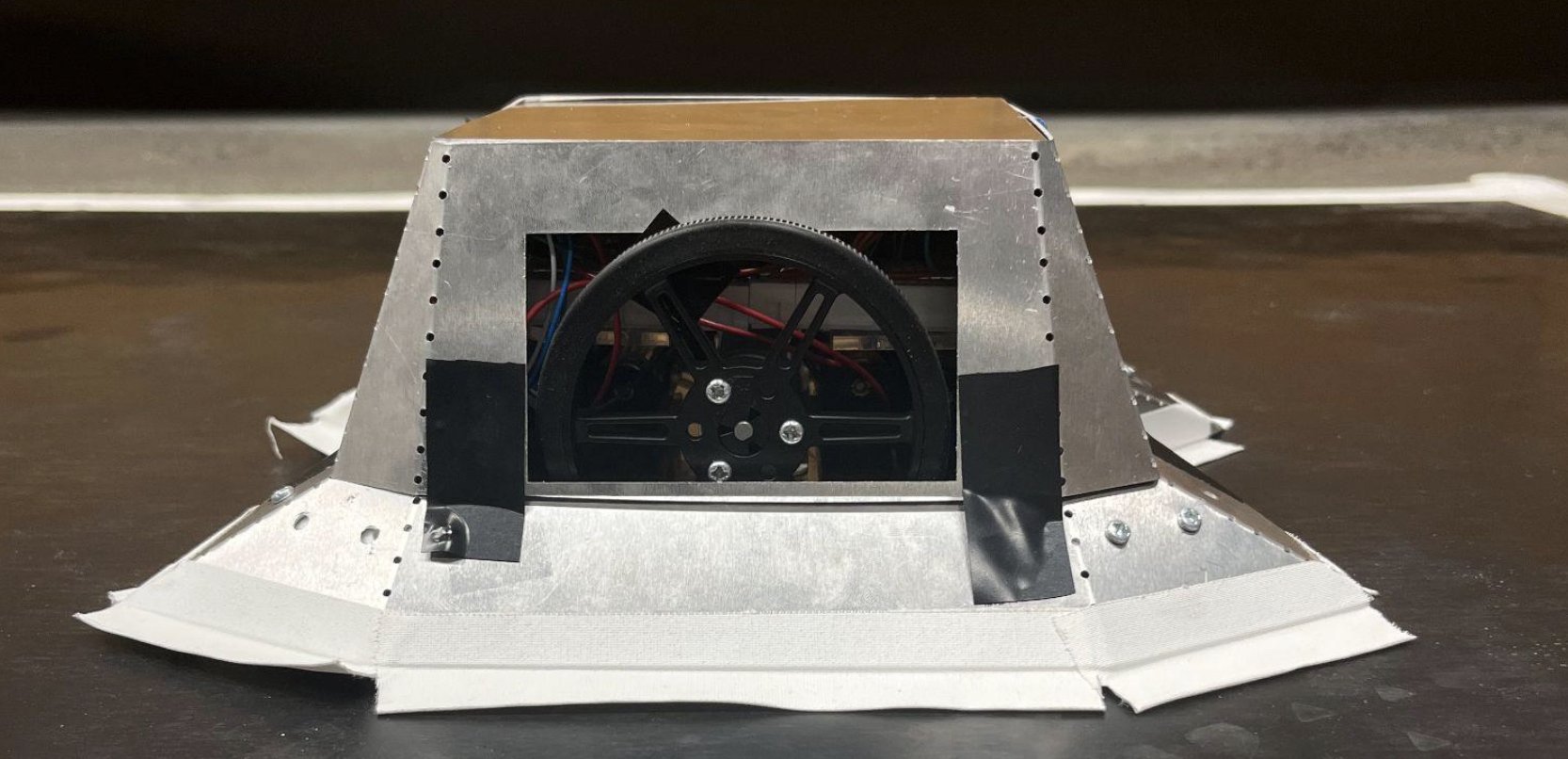

The team decided to work with a two motor design with four ball casters to keep the robot balanced. The outer shell was designed to prevent opponents from blocking the wheels and to wedge and lift opposing robots. By trapping and lifting the opponent, they would have less traction and be easier to push out of the ring. This shell was manufactured with bent sheet metal (6061 Aluminum) that was cut with a metal-laser cutter. The main chassis was laser cut from 7/32” acrylic and mounted to the shell with custom 3D printed PLA pieces.

For Mechatronics class (ME-353), teams of students designed and fabricated sumo-robots for a competition at the end of the semester. The goal for each robot was to push the opponent robot out of a 3'x3' ring and avoid getting pushed in the process. Every team was constrained in terms of the size, weight, battery voltage, battery amperage, and cost of the robot to maintain safety and keep the competition fair. Every team was also limited to using IR sensors for determining where the edge of the ring was.

The rules states that if more than half of the robot crossed over the edge of the ring, it counted as exiting the ring and would lose the match. For this reason, 4 IR sensors were used at the corners of the robot to guarantee that the microcontroller knew where the edge of the ring was.

The metal shell was split into 2 upper and lower pieces and also split into left and right halves to unfold a 2D pattern with non-overlapping faces. Because the wheels are so large to increase the traversing speed of the robot, they interfere with the side faces of the upper metal shell. For this reason, wheel-wells were cut out of the sheet metal. Perforation holes were also cut along the lines of the folding edges to make it easier to bend the metal into its final 3D shape and prevent cracking the aluminum while bending.

The robot was controlled with an ATMega8 microcontroller and a dual-motor H-bridge. Four IR sensors, located at each of the casters, were used to detect the edge of the ring. Since there were no sensors used to directly locate the opponent robot, the robot was designed to travel in straight lines toward the edges of the ring until it moved into the opponent. However, the IR sensors could detect when the robot was actively getting pushed out of the ring by the opponent if the controller sent a forward command to the motors but the rear IR sensors detected the edge of the ring. If this was the case, our robot was most likely getting overpowered by the opponent and was seconds away from getting completely pushed out. At this time our robot was programmed to reverse motor direction and spin in place to avoid getting pushed out and potentially attack the other robot from behind.

More details about the design, fabrication, and electronics for this robot are contained in the final report attached here: Mechatronics Final Report