Turducken Cooking Simulation

The first step of the project was to run simplified sample calculations of the cook time using the lumped-capacitance assumption of different portions of the turducken. This would help verify the cooking time of the simulation by giving a rough approximation for how long it should take. For this part, the 3 different components of the turducken: the turkey, the ducken, and the stuffing, were assumed to be concentric spheres of homogenous composition. Each of the components had varying percentages of water, fat, and protein, that caused their thermal properties to vary. The results of the simulation indicated that the center of the stuffing would take around 14 hours to fully cook. However, at this point all of the turkey would also be burned.

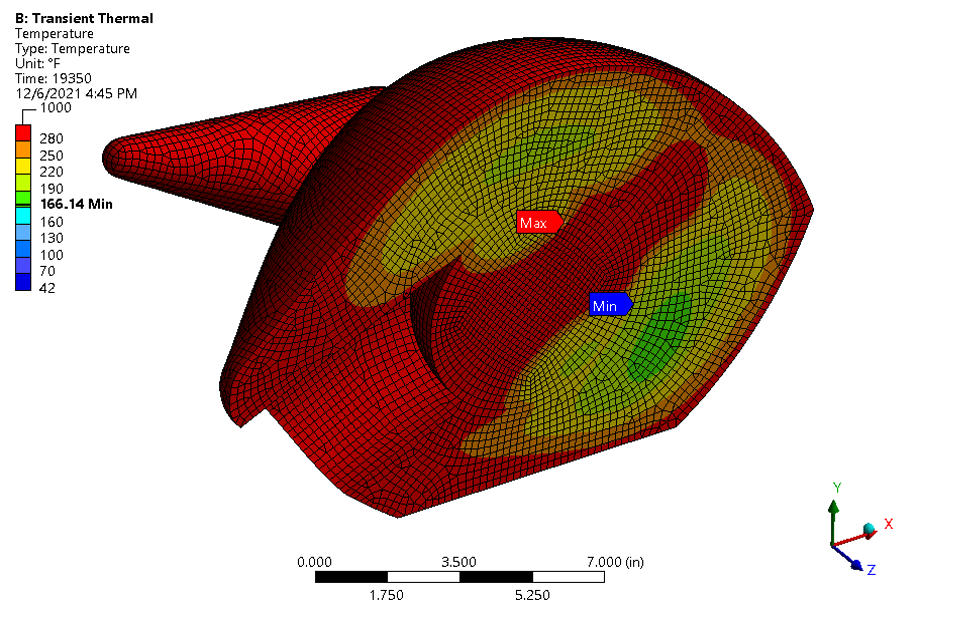

Before finalizing the skewer shape, position, and heat output, a preliminary simulation was run on the turducken cooking in only the convection oven. Any part of the turducken that is red is burned, between green and red is cooked, and anything blue is still raw. After 2 hours most of the center of the bird is still raw and only the tip of the leg is burned. After 10 hours the entire turducken is cooked. However, most of the outer layer of turkey is also burned. This timing and burning was consistent with the sample calculations done in MatLab, which made us confident in our mesh to move forward with more complicated simulations with the skewers.

The group final project for ME-408 (intro to FEA) was to design and run simulations for electrically heated skewers used to help cook the center of a turducken placed in a convection oven. To prevent convoluted instructions, the skewers were limited in count, size, and cross-section. They also had to be positioned in the turducken in a fixed location and could only change heat output twice throughout the cooking process. Similarly, the oven could only change temperature once during the cooking cycle and was limited to 350˚. The goal was to design the skewers and control the oven temperature to achieve the fastest cook time while burning the smallest volume of the bird(s) possible. The turducken starts cold at 42˚F and is considered cooked at a minimum temperature of 165˚F. Any portion above 282˚F is considered burned.

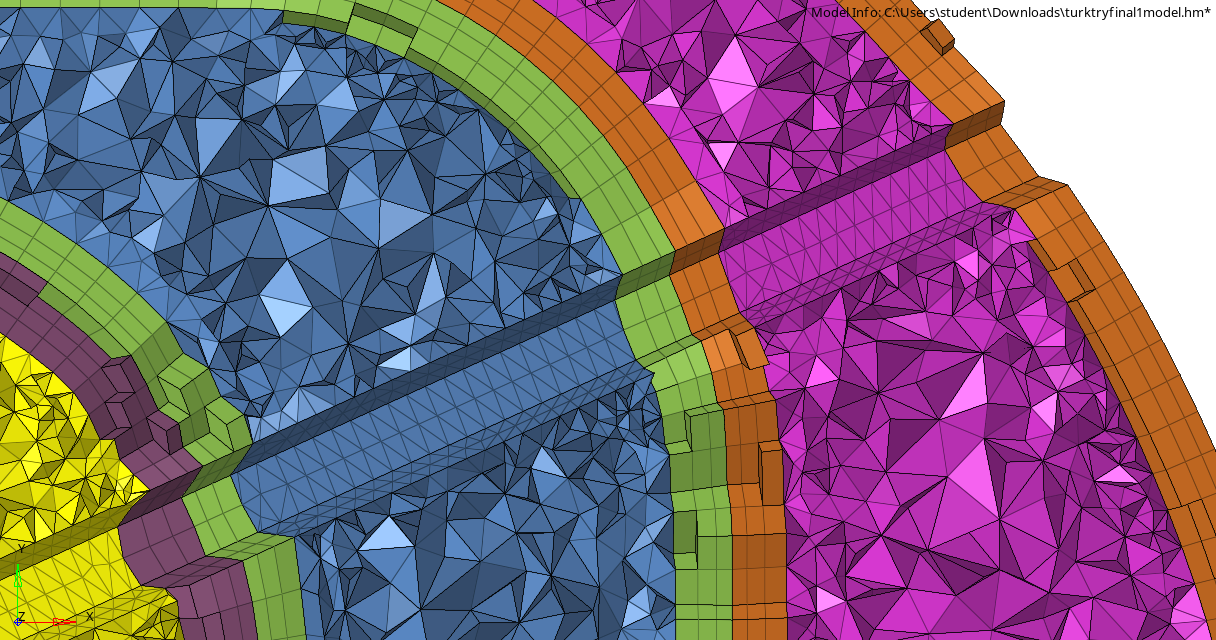

The next part was to mesh the 3D shape of the turducken into finite elements. For speed and accuracy, the outer and intersection surfaces of the 3 unique portions of the bird were surface meshed with smaller elements. Meanwhile, the inner volume was tetra meshed with larger elements. This reduced the number of elements and therefore the computation time while maintaining a large number of nodes at areas with the highest temperature differential. Furthermore, only half of the geometry of the turducken was meshed to reduce the number of nodes and elements. This was done because the geometry of the bird was symmetric and the skewer position was assumed to be symmetric at this point for simplicity.

Thermal Loads2HR

6HR

4HR

8HR

10HR

The skewers have a straight pentagon cross-section and are inserted 1+3/8” from the centerline of the bird such that they intersect through the centroid of the sphere of stuffing. The oven was set to run consistently at 350˚ and the skewers were given a heat output of 0.15 BTU/hr. With this setup, the cooking time of the bird was reduced to 5 hours and 22.5 minutes with 20% of the bird being burned. Later feedback indicated that this burn percentage is probably an overestimate because the thermal properties of the bird does not account for the additional energy required for the heat of vaporization of the water to boil.

More details on the sample calculations, mesh, and results are in the submitted final report here.